Our Products

Walking Beam Furnaces

Salient Features

30% reduction in fuel consumption

It works with F.O./LPG.

It works like billet heater

For forging and normalizing (immediate after trimming)

Comparison between EN EFF Walking Beam Furnace & Induction Billet Heater

| Sr. No. | Particular | EN EFF Walking Beam | Induction Billet Heater |

|---|---|---|---|

| 1 | Running cost (300 KGS per hour Furnace | Rs. 2.15 per KGS | Rs.4 per KGS |

| 2 | Initial Cost | Rs.10.8 Lakhs Approx | Rs.25 Lakhs Approx.(INCL.Heat exc.,DM Plant etc.) |

| 3 | Have to increase electric load | Not Required | Required |

| 4 | Have to inhance genset capacity | Not Required | Required |

| 5 | Heating Media | LPG / F.O. | Electricty |

| 6 | Scalling/Burning Losses | 1% to 1.50% / 3% (F.O.) | 1% To 1.50% |

| 7 | Cost of Spares | Normal as easily available | Costly because of monopoly |

| 8 | Engineer's visit for trouble shooting | Negligible | Minimum Rs.25000 |

| 9 | Local service | Available | Not Available |

| 10 | Additional Cost | N.A | In Punjab power intensive units have to shell out Rs. 278 per KW month as fixed charges |

| 11 | Fix cost during recession | No fixed cost | Monthly fixed cost |

| 12 | AMC contract | Not Required | Required |

| 13 | Size variation | No problem | Additional coils required |

EN EFF Walking Beam Furnaces

Our walking beam furnace is mainly used with steel industry for applications like forging, normalising, stress relieving,

hardening and tempering with a maximum operating temperature of 1300oC. The material is gradually fed through the furnace with

the help of the water cooled beams which lift and move the goods a short step at a time in the direction of transport.

The advantage of using a walking beam furnace.

Walking beam are essentially state of the art raheating furnaces that are extremely efficient & works on FIFO system. The stock to be processed is kept on stationary ridges, with a revolving beam that moves it along as well as through the furnace. This continues until the stock reaches the exit, when the revolving beam is back at the entrance of the furnace. It is reported that substantial savings are achieved in electricity and fuel consumption by the intallation of a waling beam furnace that uses a high-tech ENergy EFFicient design to regulate combustion.

Energy Efficient Furnaces

EN EFF Continuous forging furnace is designed to forge cut pieces of round

billet in most efficient way resulted in increase in production, huge reduction in oil consumption per ton of steel heated along with minimum

scaling and burning losses. Insulation coating IC510 is used inside furnace shell before refractory lining to minimize the heat losses, the temperature

at outer shell will not exceed ambient+40oC.

Stainless steel recuperator will be used to heat up combustion air with the help of flue gases resulted in huge reduction in fuel consumption.

EN EFF furnaces have temperature automation system (pneumatic combination

valve) which cut off the air and oil supply when desired temparature is

achieved.

EN EFF Continuous Forging Furnaces

We undertake design, engineering, manufacturing, erection and commissioning of various types of industrial furnaces.

Salient Features

Huge reduction in fuel consumption.

Reduction in scale/buring process.

Utilization of flue gases.

Proper selection of burners.

Automation, to avoid human errors and for maintaining uniform temperatures.

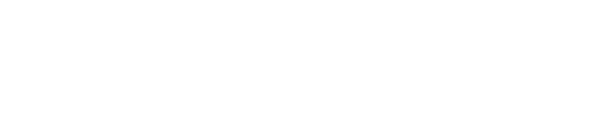

Continuous Heat Treatment Furnaces

A continuous furnace in whch grids loaded with forgings are transferred through the furnace on stainless steel or silicon carbide

rails or on a roller hearth,all in accordance with a preselectable cycle time and profile.

The plant is used for the heat treatment of forging parts with or without atmosphere.The charge baskets or grids first travel to a

high temperature furnace that reaches upto 900-950oC.Each basket then moves to a rapid (quick) cooling chamber, which is separated

by airtight intermediate doors.

The parts cool down to ISO Thermal temperature (650oC).The baskets are then conveyed to a continuous ISO Thermal annealing

furnace.The furnace enables temperatures between 600 to 750oC.After which, the parts travel to a cooling station and are then moved

to an unloading station.

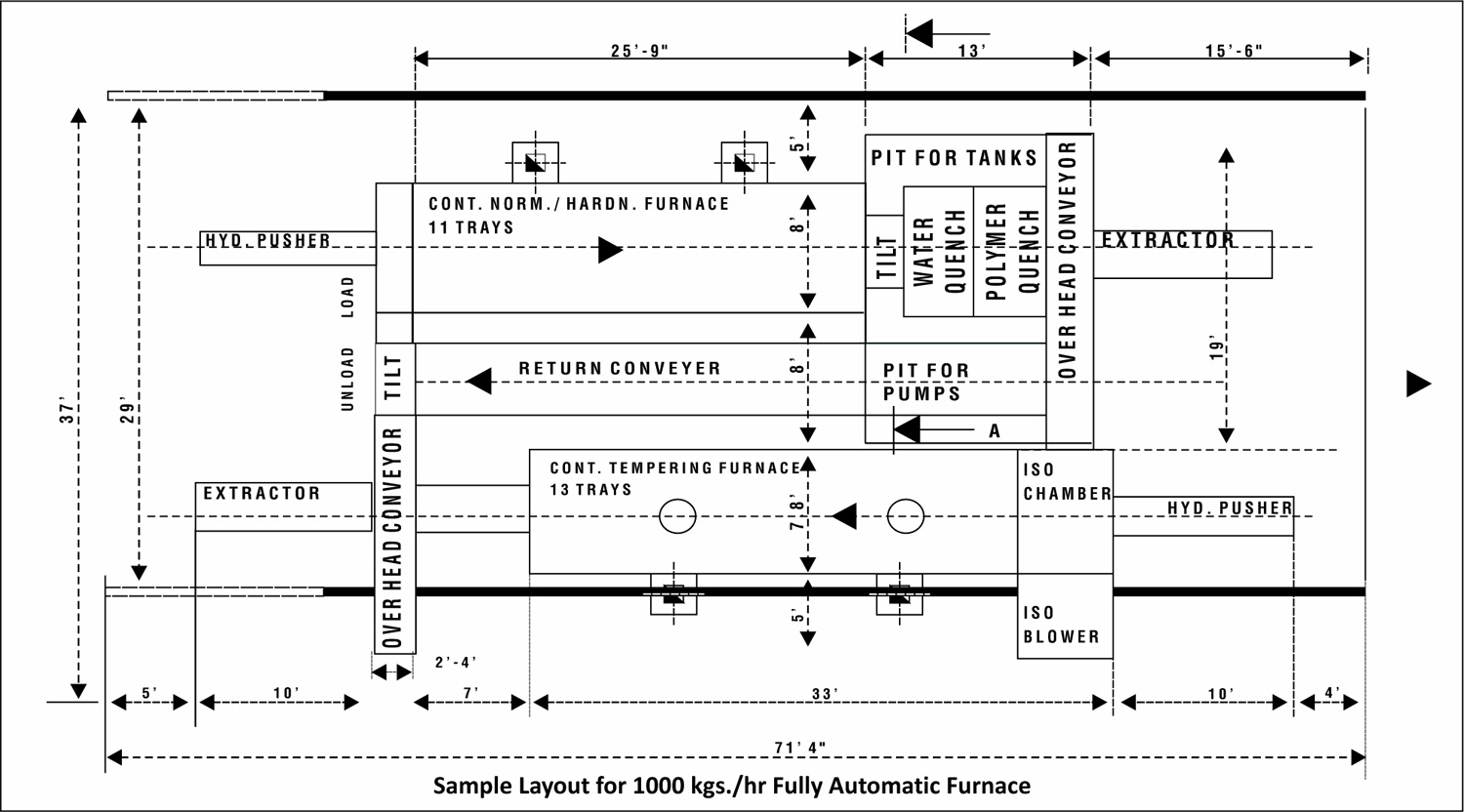

"EN EFF" Bell Type Furnaces

Our company offers a wide range of Bell Type Annealing Furnaces that are used by many industries which made product like bars,

wire, malleable casting and ferrous and non-ferrous items. These furnaces are designed to use oil, electricity or gas as its

heating media. Bell type annealing furnaces also offers a configuration with protective environment.

Spherodised Annealing of Bars

Batch capacity : 05-40T/Batch

Rectangular bell design with stationary or bogie type base

Maximum temperature 950C

Master-slave temperature control to achieve close temperature uniformity

Provision for data logging

"EN EFF" Bogie Hearth Furnace

Bogie hearth furnaces are used in applications like pre-heating,Hardening, Tempering,Annealing & normalizing of heavy components or bulk of components. These furnaces are of heavy capacities from.5 to 20 tons per batch (as per requirement of customer.)These furnaces can go up to 1200C.

"EN EFF" Muffle Furnace

These furnaces are used for heat treatment applications such as annealing, hardening, tempering & aging of aluminum, alloy steel & stainless steel etc. Solution Treatment and Homogenizing of Aluminum Products etc. Nicrome 80:20 or A-1 heating elements are used for better life.

"EN EFF" GCF Pit Type

Optimizing the most advanced technology, we provide excellent quality Pit Type GCF Furnace, which are used for heat treatment particularly for forging heat treatment in the conditions of protective atmosphere. We develop our tempering furnaces from high quality components and provide them in numerous different specifications. Our exclusive array of products are acknowledged among our global customers due to their sturdiness, application specific design and superior performance. Moreover, we also have appropriate infrastructure to design these equipment in accordance with industry standards.

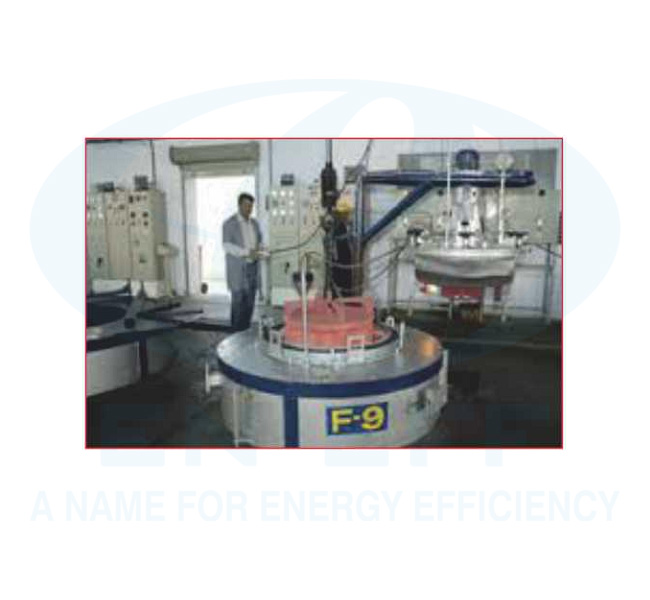

"EN EFF" Pneumatic Combination Valve

An Energy Efficient device specifically designed and developed for automation in furnaces and to reduce manual controls. It cuts off air and oil supply to burner when desired temperature is achieved and restarts after desired fall of the temperature, resulted in minimum of 10%-15% savings in fuel oil consumption,As it operates Furnace automatically,no skilled furnace operator is required. It can be used in all types of oil/gas fired furnaces whether it is forging, heat treatment or rolling mill furnace.

"EN EFF" Fuel Combustors (Blowers)

"EN EFF" Centrifugal air blower is designed to give optimum CFM volume & pressure of air with low power consumption. Each blower is

checked at par with actual working condition for vibration, Air pressure, current drawn by the motors.All blowers are equipped with

motors of reputed make such as ABB, Siemens, Havells etc.Options of direct/shaft driven through 'V' Belts.Individual units undergo

rigorous testing prior to shipment.

Salient Features

Rigid Construction.

Statically & dynamically balanced.

Quiet.

Capacity range:1HP to 80HP (Higher capacities on request)

Pressure: 6"W.g.-44"W.g.

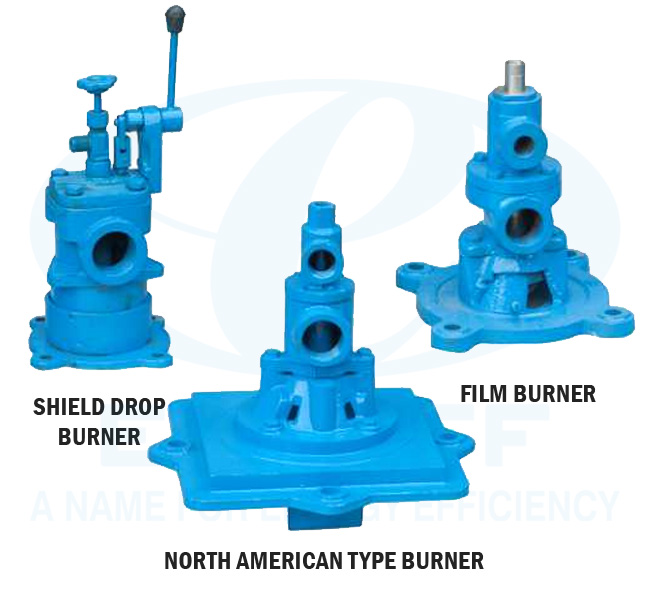

"EN EFF" Burners

The basic function of burner is to produce and maintain required and consistent degree of automization to ensure stable flame conditions and required heat distribution in the furnace. Presently there are a large number of burners with different design/types and selection has to made to suit divergent requirements as per furnace design.

Salient Features

Operates efficiently at low excess air levels.

Reduces scale/Burnings losses.

Improves fuel economy,saves up to 20% fuel.

Can be used with preheated air upto 350-400C.

Can be installed with existing systems without any significant changes.

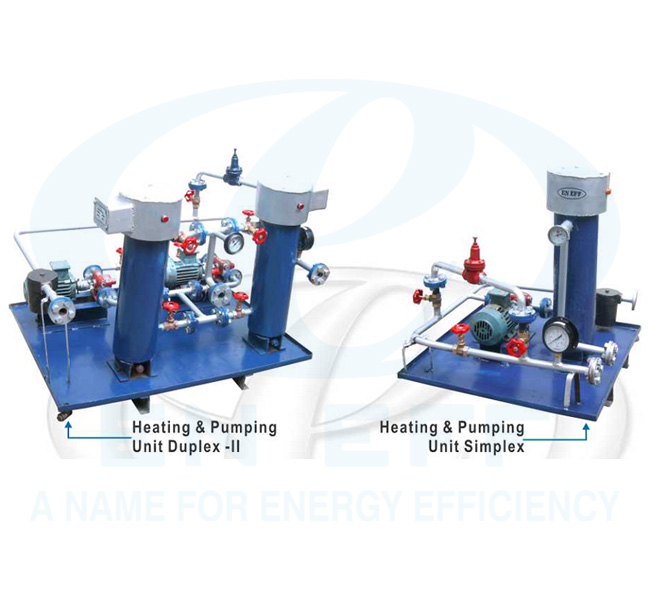

"EN EFF" Heating and Pumping Units

This device is a system which provides the fuel oil to the combustion device at a pre-determined pressure and temparature for efficient combustion.It consists motors of reputed make like ABB/Havells and rotary pump,heater with thermostati control,temperature & pressure gauges and other pressure regulating valve. These units and available in three types:-

Heating & pumping unit Simplex.

Heating & pumping unit Duplex-I

Heating & Pumping unit Duplex-II

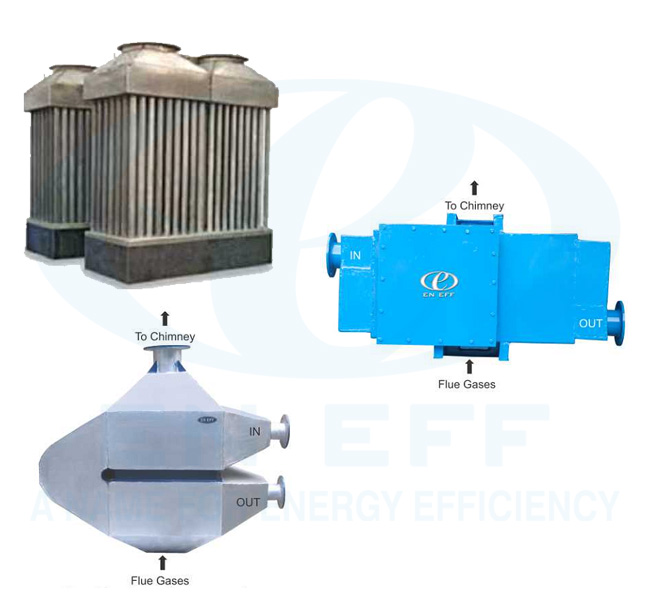

"EN EFF" Waste Heat Recovery Systems (Recuperators)

In view of the rising cost & lower supply of fuel oil all over the world and accute need to conserve the available fuel resources has been felt

to offset the slackening industrial and economic growth.

EN EFF recuperators which preheats the combustion air with the help of escaping flue gases to a temperature of 200-400 C results in recycling of

waste heat back to the furnaces to give saving of 12-15% of furnace oil.The normal pay back period on installation is just 2-3 months.EN EFF

Recuperators have been developed and are being marketed to meet the requirements of steel,forging,heat treatment and aluminum industries etc in

the country.Recuperators are manufactured in different designs.

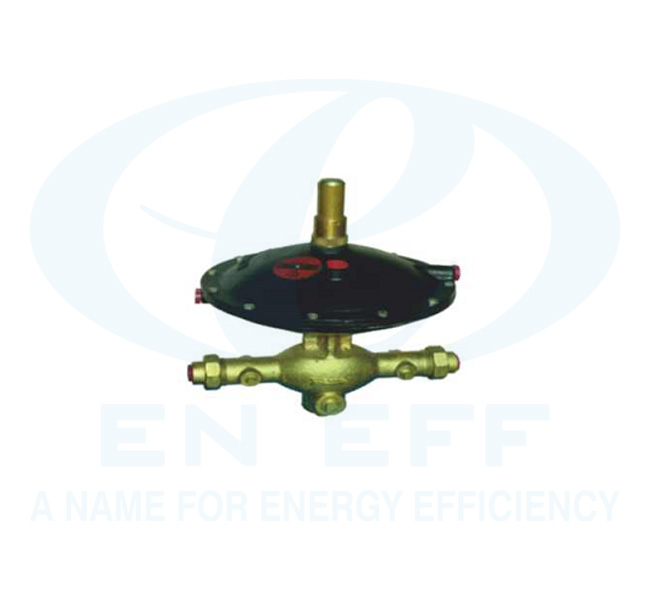

"EN EFF" Ratiotrol Oil Valves

Ratiotrol valves are accurate and used for automatic control proportioning of oil an air flow.Ratiotrol valves maintains the balance between fuel and combusion air for complete combustion in burner.It is used to control burner from high-fire to low-fire and vice versa i.e, combustion air is turned up or down, the Ratiotrol controls the oil to flow in proportion.

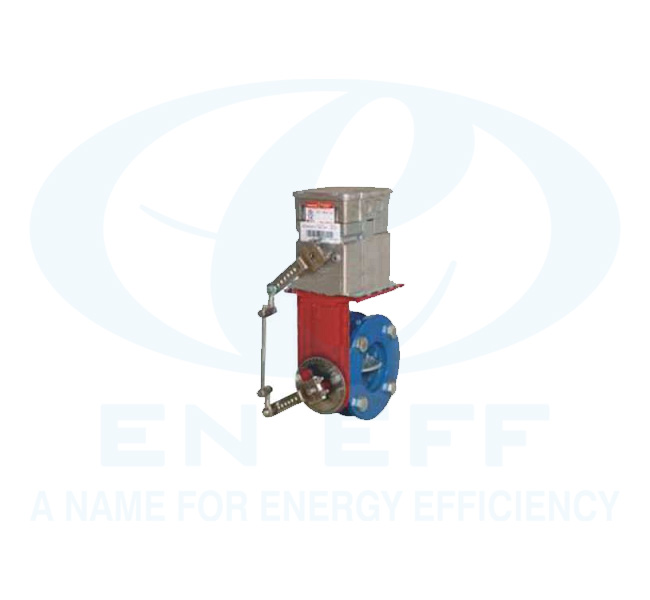

"EN EFF" Motorised Control Valves and Electrical Actuators

Butterfly,Port and Globe Valves coupled with Electrical Actuators.

Constructed Butterfly Dampers for Hot and Ambient Combustion Air.

Electrical Actuators available with Modulating (4-20mA/0-10 VDC etc.),Floating and ON-OFF options.

Different Torque options available in Electrical Actuators for Automation of Ball Valves,Butterfly valves,Globe Valves,Adjustable Port Valves

etc.

Supply Voltage Options like 24Vac & DC,110Vac,230 Vac.

Various Control Input options available like 0-10VDC, 1-5VDC

Auxillary Switch and Position Feedback Options.

Torque range from 5 Nm.

Suitable Mounting bracket and Linkages can be provided for larger Quantity requirements.

"EN EFF" Professional High Temperature Infrared Thermometer

Range : 50Cto 1850C

Resolution : 0.1 up 1000, 1 over 1000

Response Time : Less then 150ms

Emissivity : Adjustable 0.10 to 1.0

Salient Features

User Selectable C or F

Over Range Indication

Dual Laser Targeting

Type K Input

White Backlight LCD Display

USB interface

"EN EFF" Temperature Automation Valves

| Model | NF510ACT |

| Body | Gray Iron / Cast Iron |

| Size Range | 1/2" to 24" |

| Shaft | AISI 410 / AISI 304 / AISI 316 / AISI 316L |

| Disc. | Gray Iron / Cast Iron / SS 304 / SS 310 |

| Seat | Nitrile / EPDM / Neoprene |

| Seat Leakage | Tight Shut Off |

| Temperature |

20oC to 110oC (High Temperature available on Request) |

| Pressure rating | PN 10 / PN 16 (PN 20 ON REQUEST) |

| End Connection | Wafer Type Suit 150#, Table 'D', 'E' |

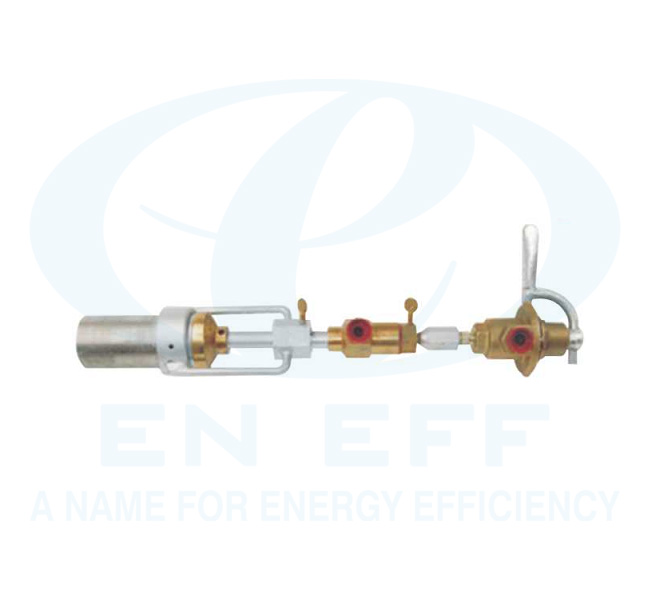

"EN EFF" Hand Held Burner

EN EFF Hand Held Burners are sturdily constructed, light in weight, easy to use and suitable for heating dies in forging industries, skin drawing moulds in foundries, leathers & ladle lips in die casting plants and many other applications like fire improvised furnaces, pre-heat casting for welding & supply heat to various kinds of highway maintenance equipment.A senstrol valve (to control oil) and valve (to control compressed air)is required for its operation.

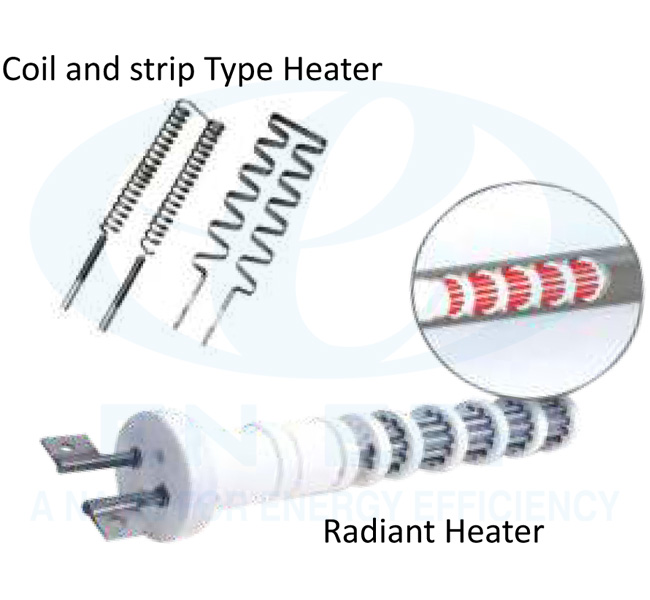

"EN EFF" Heating Elements

Most heating elements are manufactured using Nichrome 80/20 (80% nickel,20% chromium) wire, ribbon,or strip.Nichrome 80/20 is an ideal material because it has relatively high resistance and forms an adherent layer of chromium oxide when it is heated for the first time.Material beneath this layer will not oxidize, preventing the wire from breaking or burning out. We are engaged in manufacturing and supplying a comprehensive range of industrial Heaters such as Tubblar Air Heaters, Finned Air Heaters, D-Shape Heaters, Heating Elements,furnace Heating Elements and Element Holding Refractory Bricks.

"EN EFF" Insulation Coating IC-510

Get "High" heat protection that surpasses conventional insulation with IC-510 Insulation Plants.IC-510 is a ceramic based, water-borne insulating

coating designed to insulate in high temperature situations.Use IC-510 coating as a base coat/primer of build layers for additional protection.

This insulation method is much different than the traditional "wrap" insulation materials that only slow downn the loss of heat(Known as R-rating

or "heat transfer").The eight ceramic compounds create a barrier to catch and hold heat on the surface of the unit e.g.steam pipe,furnace

surface,boiler,hot air pipe line etc.Unlike wraps that use air as the insulation component, the ceramic compounds in IC-510 Coating have very

high heat emisivity.Additional benefits of IC-510 Coating include.

Easy to Apply : Apply directly to hot pipes while operating.Apply thin coat first and after surface reduces heat level,thicker coats can be applied.

Increased Insulation : Two Coats(Approx35microns)Immediately reduce surface temperature and loss of heat upto-40%

Long Lasting : Does not absorb humidity or lose insulation value.

Corrosion : No sign of corrosion of condensation.

Coverage : Can be fit over any configuration or shape.

Emissivity : Very high emissivity of 90%

"EN EFF" Heat Resistant Coating

EN EFF heat resistant coating can withstand high temperatures upto 1800C

Hide refractory joints

Apply directly on the refractory lining

Insulation property

Improves refractory life

Can be used for repairs